CT button laser engraving performance has been greatly improved

Release Time : 2025-03-31

With the rapid development of science and technology, laser engraving technology is increasingly used in various fields. Especially in the manufacturing process of electronic products, laser engraving has become an important means to improve production efficiency and product quality with its high precision, high efficiency and non-contact processing. As an important component in modern electronic equipment, the improvement of CT (Computed Tomography) button laser engraving performance is of great significance to improving product functions and user experience.

1. Overview of CT button laser engraving technology

CT button usually refers to the button used to trigger the computed tomography function or similar operations in electronic equipment. These buttons usually require high precision, high reliability and good visual effects. As an advanced processing method, laser engraving technology can meet these requirements and provide strong support for the manufacture of CT buttons.

Laser engraving technology uses high-energy laser beams to accurately engrave on various materials, thereby realizing the printing of text, patterns or functions. Its working principle is to cause chemical and physical changes in the surface material through the interaction between the laser beam and the surface of the material, thereby etching traces or directly ablating part of the material through light energy to show the required graphics and text. In the manufacturing process of CT buttons, laser engraving technology can achieve high-precision pattern and text engraving while ensuring the flatness and durability of the buttons.

2. Key factors for improving the performance of laser engraving of CT buttons

In recent years, the performance of laser engraving of CT buttons has been greatly improved, mainly due to the following key factors:

Upgrade of laser engraving equipment

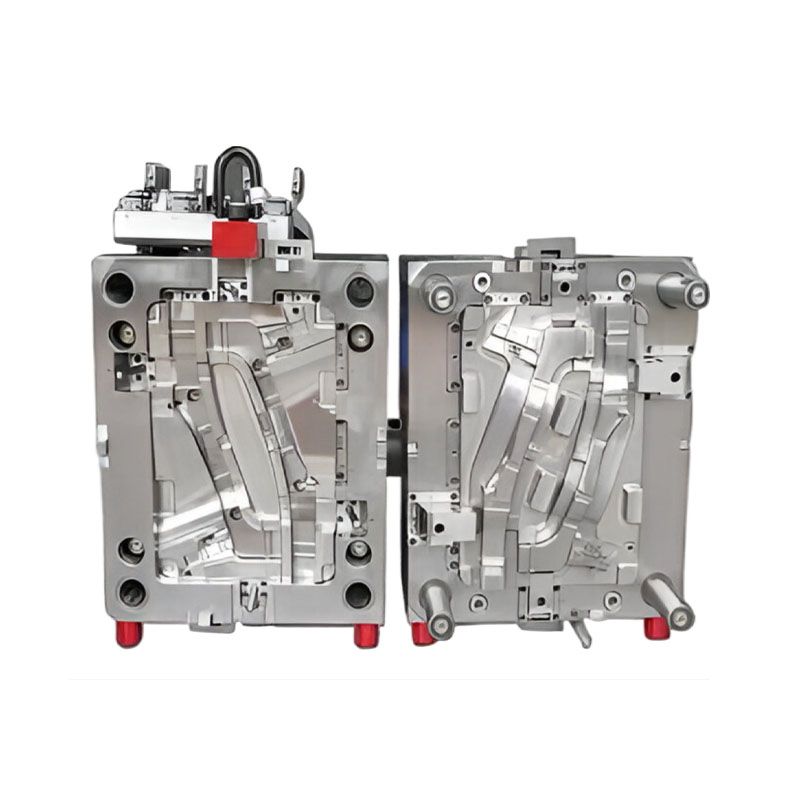

The performance of laser engraving equipment directly affects the quality and efficiency of engraving. With the continuous advancement of technology, laser engraving equipment has been significantly improved in terms of power, precision and stability. For example, modern laser engraving machines usually use advanced CNC technology and laser transmission systems to achieve high-precision engraving and cutting. In addition, the stability and durability of the equipment have also been improved, making the laser engraving process more reliable and efficient.

Optimization of laser engraving materials

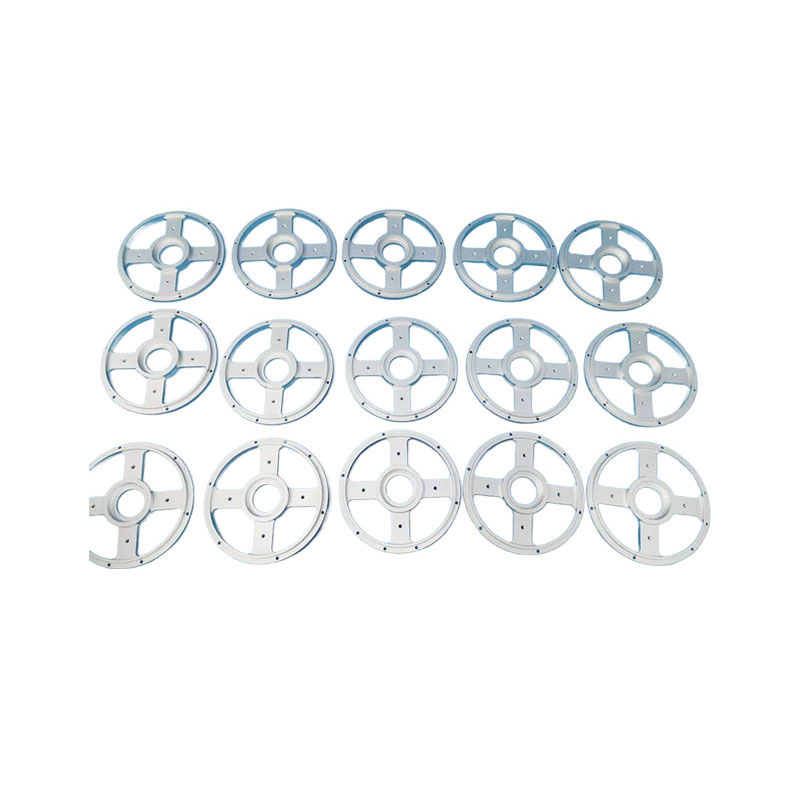

The laser engraving performance of CT buttons depends not only on the equipment itself, but also on the materials used. In order to improve the laser engraving effect, manufacturers continue to develop and optimize materials suitable for laser engraving. These materials usually have better laser absorption and thermal stability, and can achieve more precise engraving effects under laser irradiation. At the same time, these materials also have good wear resistance and corrosion resistance, which can extend the service life of CT buttons.

Innovation of laser engraving technology

Innovation of laser engraving technology is also one of the key factors to improve the performance of CT buttons. By optimizing engraving parameters (such as laser power, engraving speed, spot size, etc.), a finer and more uniform engraving effect can be achieved. In addition, different engraving methods such as dot matrix engraving and vector cutting can be used to meet different materials and design requirements. The application of these innovative processes makes the laser engraving effect of CT buttons more beautiful and practical.

Application of intelligent and automated technology

With the continuous development of intelligent and automated technology, the laser engraving process has become more and more intelligent and automated. Modern laser engraving equipment is usually equipped with advanced computer control systems, which can achieve flexible production processes and automated operations. Through preset programs and parameters, the equipment can automatically complete the engraving task, reducing manual intervention and error rate. This not only improves production efficiency, but also ensures the stability and consistency of product quality.

3. Specific performance of CT button laser engraving performance improvement

The improvement of CT button laser engraving performance has been reflected in many aspects, including engraving accuracy, engraving efficiency, engraving quality and production cost.

Greatly improved engraving accuracy

With the continuous advancement of laser engraving technology, the engraving accuracy of CT buttons has been greatly improved. Modern laser engraving machines can usually achieve an accuracy of 0.02mm or even higher, which can meet the manufacturing needs of CT buttons with extremely high requirements for details. This makes the patterns and text on the CT buttons clearer and finer, improving the visual effect and user experience of the product.

Significantly improved engraving efficiency

Laser engraving technology is known for its high efficiency. Modern laser engraving equipment usually uses high-speed laser beams and advanced control systems to complete complex engraving tasks in a short time. This not only improves production efficiency, but also reduces production costs. For mass-produced CT buttons, the efficiency of laser engraving technology is particularly important.

More stable and reliable engraving quality

The laser engraving process is dust-free and pollution-free, and the beam and spot diameter are small, which can accurately control the engraving depth and width. This makes the engraving quality of CT buttons more stable and reliable, avoiding problems such as damage, deformation or contamination caused by mechanical contact. At the same time, laser engraving also has good wear resistance and corrosion resistance, which can extend the service life of CT buttons.

Effectively reduce production costs

The application of laser engraving technology reduces the production cost of CT buttons. On the one hand, the laser engraving process does not require auxiliary tools such as molds and cutters, reducing material consumption and processing costs; on the other hand, the high efficiency and stability of laser engraving equipment improve production efficiency and reduce labor costs and time costs. This effectively controls the production cost of CT buttons and improves the market competitiveness of products.

4. Application cases of improved laser engraving performance of CT buttons

The following are several application cases of improved laser engraving performance of CT buttons, showing the wide application and significant effects of laser engraving technology in electronic product manufacturing.

CT buttons in smartphones

Smartphones are one of the representatives of modern electronic products, and the CT buttons in them are usually used to trigger cameras, flashlights or other specific functions. Through laser engraving technology, patterns and texts can be accurately engraved on these buttons to improve the beauty and ease of use of the products. For example, some smartphones have exquisite patterns or brand logos engraved on the camera buttons, which not only improves the visual effect of the product, but also enhances the brand identity.

CT buttons in medical devices

CT buttons in medical devices are usually used to trigger scanning, positioning or diagnostic functions. These buttons require high precision and high reliability to ensure the accuracy and safety of medical procedures. Through laser engraving technology, functional logos and warning texts can be accurately engraved on these buttons to improve the readability and ease of use of the product. At the same time, the wear resistance and corrosion resistance of laser engraving also ensure the stability and reliability of the buttons in long-term use.

CT buttons in smart home devices

CT buttons in smart home devices are usually used to control the switch of the device, adjust the volume or set the timing and other functions. These buttons are required to be beautiful, durable and easy to operate. Through laser engraving technology, exquisite patterns and texts can be engraved on these buttons to improve the visual effect and user experience of the product. At the same time, the fineness and uniformity of laser engraving also ensure the flatness and comfort of the button, and improve the overall quality of the product.

With the continuous advancement of technology and the continuous expansion of application fields, CT button laser engraving technology will continue to develop in the direction of higher precision, higher efficiency and wider application.

Higher precision engraving

With the continuous development of laser technology, the laser engraving accuracy of CT buttons will be further improved in the future. This will make the patterns and texts on the CT buttons more refined and clear, and improve the visual effect and user experience of the product. At the same time, higher precision engraving will also provide more possibilities for the design of CT buttons and meet more diverse needs.

More efficient engraving

Modern laser engraving equipment is already highly efficient, but there is still room for further improvement in the future. A more efficient engraving process can be achieved by optimizing the equipment structure, improving the laser power and the performance of the control system. This will reduce production costs, improve production efficiency and meet the needs of large-scale production.

Wider applications

With the continuous development of intelligent and automated technologies, laser engraving technology will be applied in more fields. In addition to CT buttons, laser engraving technology can also be applied to the manufacturing process of other electronic products (such as tablets, smart watches, etc.). In addition, with the continuous emergence of new materials and new processes, laser engraving technology will continue to expand its application scope and provide more innovative solutions for electronic product manufacturing.

Intelligent and automated trends

In the future, laser engraving equipment will be more intelligent and automated. By integrating intelligent devices such as sensors, controllers and actuators, functions such as real-time monitoring of equipment status, fault prediction and remote control can be realized. This will improve the stability and reliability of equipment operation, reduce maintenance costs and enhance user experience. At the same time, intelligent and automated laser engraving equipment will also provide a more flexible and efficient production process for electronic product manufacturing.

The substantial improvement in the performance of CT button laser engraving is due to the upgrade of laser engraving equipment, optimization of materials, innovation of processes, and the application of intelligent and automated technologies. These advances have enabled CT buttons to achieve remarkable results in terms of engraving accuracy, efficiency, quality, and production costs. In the future, with the continuous advancement of technology and the continuous expansion of application areas, CT button laser engraving technology will continue to develop in the direction of higher accuracy, higher efficiency, and wider application. This will provide more innovative solutions for electronic product manufacturing and promote the continuous development and progress of the industry.

1. Overview of CT button laser engraving technology

CT button usually refers to the button used to trigger the computed tomography function or similar operations in electronic equipment. These buttons usually require high precision, high reliability and good visual effects. As an advanced processing method, laser engraving technology can meet these requirements and provide strong support for the manufacture of CT buttons.

Laser engraving technology uses high-energy laser beams to accurately engrave on various materials, thereby realizing the printing of text, patterns or functions. Its working principle is to cause chemical and physical changes in the surface material through the interaction between the laser beam and the surface of the material, thereby etching traces or directly ablating part of the material through light energy to show the required graphics and text. In the manufacturing process of CT buttons, laser engraving technology can achieve high-precision pattern and text engraving while ensuring the flatness and durability of the buttons.

2. Key factors for improving the performance of laser engraving of CT buttons

In recent years, the performance of laser engraving of CT buttons has been greatly improved, mainly due to the following key factors:

Upgrade of laser engraving equipment

The performance of laser engraving equipment directly affects the quality and efficiency of engraving. With the continuous advancement of technology, laser engraving equipment has been significantly improved in terms of power, precision and stability. For example, modern laser engraving machines usually use advanced CNC technology and laser transmission systems to achieve high-precision engraving and cutting. In addition, the stability and durability of the equipment have also been improved, making the laser engraving process more reliable and efficient.

Optimization of laser engraving materials

The laser engraving performance of CT buttons depends not only on the equipment itself, but also on the materials used. In order to improve the laser engraving effect, manufacturers continue to develop and optimize materials suitable for laser engraving. These materials usually have better laser absorption and thermal stability, and can achieve more precise engraving effects under laser irradiation. At the same time, these materials also have good wear resistance and corrosion resistance, which can extend the service life of CT buttons.

Innovation of laser engraving technology

Innovation of laser engraving technology is also one of the key factors to improve the performance of CT buttons. By optimizing engraving parameters (such as laser power, engraving speed, spot size, etc.), a finer and more uniform engraving effect can be achieved. In addition, different engraving methods such as dot matrix engraving and vector cutting can be used to meet different materials and design requirements. The application of these innovative processes makes the laser engraving effect of CT buttons more beautiful and practical.

Application of intelligent and automated technology

With the continuous development of intelligent and automated technology, the laser engraving process has become more and more intelligent and automated. Modern laser engraving equipment is usually equipped with advanced computer control systems, which can achieve flexible production processes and automated operations. Through preset programs and parameters, the equipment can automatically complete the engraving task, reducing manual intervention and error rate. This not only improves production efficiency, but also ensures the stability and consistency of product quality.

3. Specific performance of CT button laser engraving performance improvement

The improvement of CT button laser engraving performance has been reflected in many aspects, including engraving accuracy, engraving efficiency, engraving quality and production cost.

Greatly improved engraving accuracy

With the continuous advancement of laser engraving technology, the engraving accuracy of CT buttons has been greatly improved. Modern laser engraving machines can usually achieve an accuracy of 0.02mm or even higher, which can meet the manufacturing needs of CT buttons with extremely high requirements for details. This makes the patterns and text on the CT buttons clearer and finer, improving the visual effect and user experience of the product.

Significantly improved engraving efficiency

Laser engraving technology is known for its high efficiency. Modern laser engraving equipment usually uses high-speed laser beams and advanced control systems to complete complex engraving tasks in a short time. This not only improves production efficiency, but also reduces production costs. For mass-produced CT buttons, the efficiency of laser engraving technology is particularly important.

More stable and reliable engraving quality

The laser engraving process is dust-free and pollution-free, and the beam and spot diameter are small, which can accurately control the engraving depth and width. This makes the engraving quality of CT buttons more stable and reliable, avoiding problems such as damage, deformation or contamination caused by mechanical contact. At the same time, laser engraving also has good wear resistance and corrosion resistance, which can extend the service life of CT buttons.

Effectively reduce production costs

The application of laser engraving technology reduces the production cost of CT buttons. On the one hand, the laser engraving process does not require auxiliary tools such as molds and cutters, reducing material consumption and processing costs; on the other hand, the high efficiency and stability of laser engraving equipment improve production efficiency and reduce labor costs and time costs. This effectively controls the production cost of CT buttons and improves the market competitiveness of products.

4. Application cases of improved laser engraving performance of CT buttons

The following are several application cases of improved laser engraving performance of CT buttons, showing the wide application and significant effects of laser engraving technology in electronic product manufacturing.

CT buttons in smartphones

Smartphones are one of the representatives of modern electronic products, and the CT buttons in them are usually used to trigger cameras, flashlights or other specific functions. Through laser engraving technology, patterns and texts can be accurately engraved on these buttons to improve the beauty and ease of use of the products. For example, some smartphones have exquisite patterns or brand logos engraved on the camera buttons, which not only improves the visual effect of the product, but also enhances the brand identity.

CT buttons in medical devices

CT buttons in medical devices are usually used to trigger scanning, positioning or diagnostic functions. These buttons require high precision and high reliability to ensure the accuracy and safety of medical procedures. Through laser engraving technology, functional logos and warning texts can be accurately engraved on these buttons to improve the readability and ease of use of the product. At the same time, the wear resistance and corrosion resistance of laser engraving also ensure the stability and reliability of the buttons in long-term use.

CT buttons in smart home devices

CT buttons in smart home devices are usually used to control the switch of the device, adjust the volume or set the timing and other functions. These buttons are required to be beautiful, durable and easy to operate. Through laser engraving technology, exquisite patterns and texts can be engraved on these buttons to improve the visual effect and user experience of the product. At the same time, the fineness and uniformity of laser engraving also ensure the flatness and comfort of the button, and improve the overall quality of the product.

With the continuous advancement of technology and the continuous expansion of application fields, CT button laser engraving technology will continue to develop in the direction of higher precision, higher efficiency and wider application.

Higher precision engraving

With the continuous development of laser technology, the laser engraving accuracy of CT buttons will be further improved in the future. This will make the patterns and texts on the CT buttons more refined and clear, and improve the visual effect and user experience of the product. At the same time, higher precision engraving will also provide more possibilities for the design of CT buttons and meet more diverse needs.

More efficient engraving

Modern laser engraving equipment is already highly efficient, but there is still room for further improvement in the future. A more efficient engraving process can be achieved by optimizing the equipment structure, improving the laser power and the performance of the control system. This will reduce production costs, improve production efficiency and meet the needs of large-scale production.

Wider applications

With the continuous development of intelligent and automated technologies, laser engraving technology will be applied in more fields. In addition to CT buttons, laser engraving technology can also be applied to the manufacturing process of other electronic products (such as tablets, smart watches, etc.). In addition, with the continuous emergence of new materials and new processes, laser engraving technology will continue to expand its application scope and provide more innovative solutions for electronic product manufacturing.

Intelligent and automated trends

In the future, laser engraving equipment will be more intelligent and automated. By integrating intelligent devices such as sensors, controllers and actuators, functions such as real-time monitoring of equipment status, fault prediction and remote control can be realized. This will improve the stability and reliability of equipment operation, reduce maintenance costs and enhance user experience. At the same time, intelligent and automated laser engraving equipment will also provide a more flexible and efficient production process for electronic product manufacturing.

The substantial improvement in the performance of CT button laser engraving is due to the upgrade of laser engraving equipment, optimization of materials, innovation of processes, and the application of intelligent and automated technologies. These advances have enabled CT buttons to achieve remarkable results in terms of engraving accuracy, efficiency, quality, and production costs. In the future, with the continuous advancement of technology and the continuous expansion of application areas, CT button laser engraving technology will continue to develop in the direction of higher accuracy, higher efficiency, and wider application. This will provide more innovative solutions for electronic product manufacturing and promote the continuous development and progress of the industry.