Efficient customization, leading technology, affordable price, one-stop plastic mold processing

Release Time : 2025-03-10

In today's ever-changing manufacturing industry, plastic mold processing technology is a key link in the production of plastic products, and its importance is self-evident. In order to meet the high-precision and high-efficiency requirements of various industries for batch product mold opening, we provide a one-stop plastic mold processing solution. With advanced technology, preferential prices and precise customization services, we are committed to becoming your trusted partner.

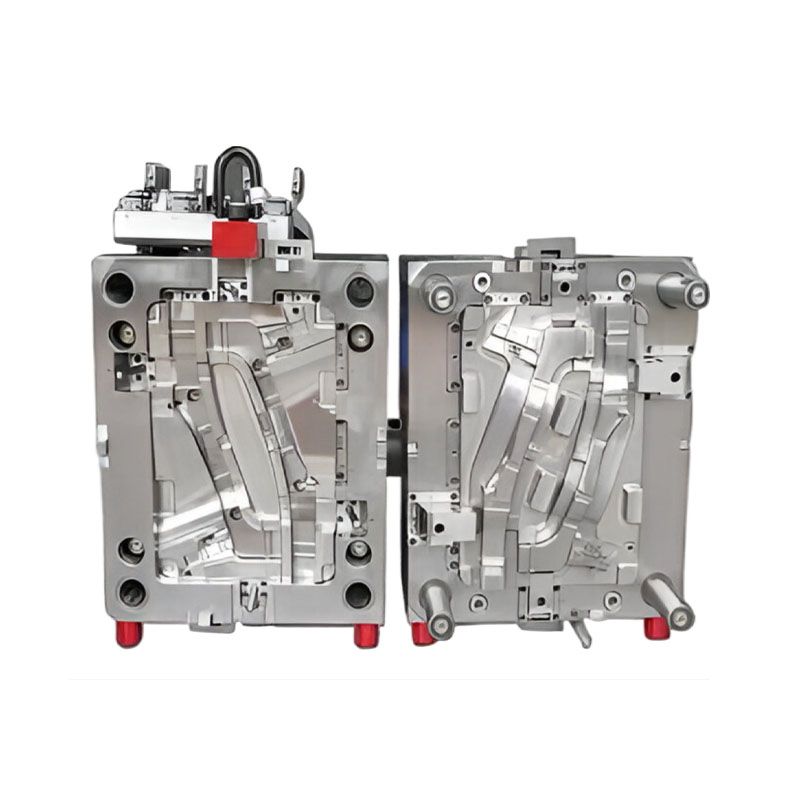

1. Advanced technology, rapid conversion from drawings to molds

We have advanced CAD/CAM systems, which can quickly and accurately design molds according to the drawings provided by customers. Through the use of advanced technologies such as laser rapid prototyping and CNC machining, we can achieve rapid customization from drawings to molds. Whether it is a complex structure or high-precision requirements, we can ensure that the processing accuracy of the mold reaches the industry-leading level.

2. One-stop service, worry-free and labor-saving

From drawing analysis, mold design, material selection to processing and manufacturing, quality inspection, we provide one-stop service. Customers only need to provide drawings or product concepts, and we can tailor the most suitable mold processing plan for them. This one-stop service model not only saves customers' time and energy, but also ensures the efficiency and accuracy of the mold processing process.

3. Affordable price and high cost performance

We are well aware of the importance of cost control to customers. Therefore, while ensuring the quality of mold processing, we are also committed to providing preferential prices. By optimizing the production process, improving production efficiency and adopting advanced processing technology, we can effectively reduce production costs, thereby passing on more benefits to customers.

4. Wide application to meet the needs of various industries

Our plastic mold processing solution is suitable for product mold opening needs in various industries. Whether it is daily necessities, automotive parts or electronic products, we can provide high-quality mold processing services. At the same time, we can also customize according to the specific needs of customers to ensure that the mold can meet their specific production requirements.

5. High-precision processing to ensure product quality

During the mold processing process, we strictly follow industry standards and technical specifications to ensure that every processing link meets high precision requirements. By adopting advanced testing equipment and quality control methods, we can monitor the processing quality and dimensional accuracy of the mold in real time, thereby ensuring the quality and stability of the final product.

In summary, the highly efficient, customized, technologically advanced, and affordable plastic mold processing solutions we provide are designed to meet the high-precision and high-efficiency requirements of various industries for batch product mold opening. We look forward to working with you to jointly promote the development and innovation of the manufacturing industry.

1. Advanced technology, rapid conversion from drawings to molds

We have advanced CAD/CAM systems, which can quickly and accurately design molds according to the drawings provided by customers. Through the use of advanced technologies such as laser rapid prototyping and CNC machining, we can achieve rapid customization from drawings to molds. Whether it is a complex structure or high-precision requirements, we can ensure that the processing accuracy of the mold reaches the industry-leading level.

2. One-stop service, worry-free and labor-saving

From drawing analysis, mold design, material selection to processing and manufacturing, quality inspection, we provide one-stop service. Customers only need to provide drawings or product concepts, and we can tailor the most suitable mold processing plan for them. This one-stop service model not only saves customers' time and energy, but also ensures the efficiency and accuracy of the mold processing process.

3. Affordable price and high cost performance

We are well aware of the importance of cost control to customers. Therefore, while ensuring the quality of mold processing, we are also committed to providing preferential prices. By optimizing the production process, improving production efficiency and adopting advanced processing technology, we can effectively reduce production costs, thereby passing on more benefits to customers.

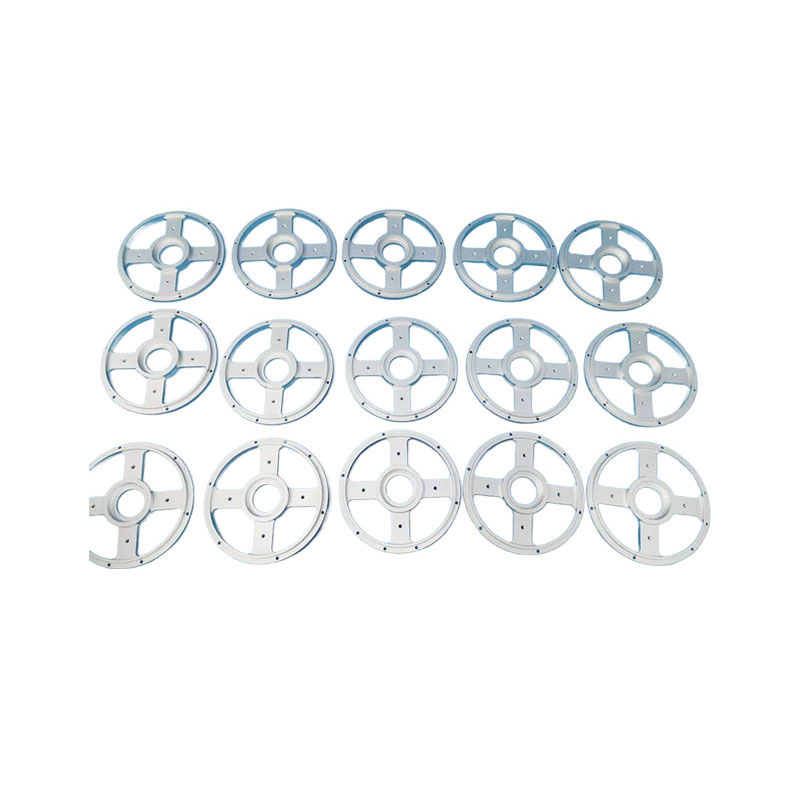

4. Wide application to meet the needs of various industries

Our plastic mold processing solution is suitable for product mold opening needs in various industries. Whether it is daily necessities, automotive parts or electronic products, we can provide high-quality mold processing services. At the same time, we can also customize according to the specific needs of customers to ensure that the mold can meet their specific production requirements.

5. High-precision processing to ensure product quality

During the mold processing process, we strictly follow industry standards and technical specifications to ensure that every processing link meets high precision requirements. By adopting advanced testing equipment and quality control methods, we can monitor the processing quality and dimensional accuracy of the mold in real time, thereby ensuring the quality and stability of the final product.

In summary, the highly efficient, customized, technologically advanced, and affordable plastic mold processing solutions we provide are designed to meet the high-precision and high-efficiency requirements of various industries for batch product mold opening. We look forward to working with you to jointly promote the development and innovation of the manufacturing industry.