Dongguan Quick Plastic Products Co., Ltd.

Dongguan Quick Plastic Products Co., Ltd. was established in 2013. It is a professional manufacturer engaged in mold manufacturing, prototype processing, parts processing, and injection molding.

The company has domestic advanced mold processing and injection molding equipment, a strong design and development team, and can provide customers with a series of services from product design, prototype processing, mold production to injection molding. The company has passed the ISO 9001 quality management system certification, and strictly controls every link from raw material procurement to product delivery to ensure that the products meet international standards and customer requirements.

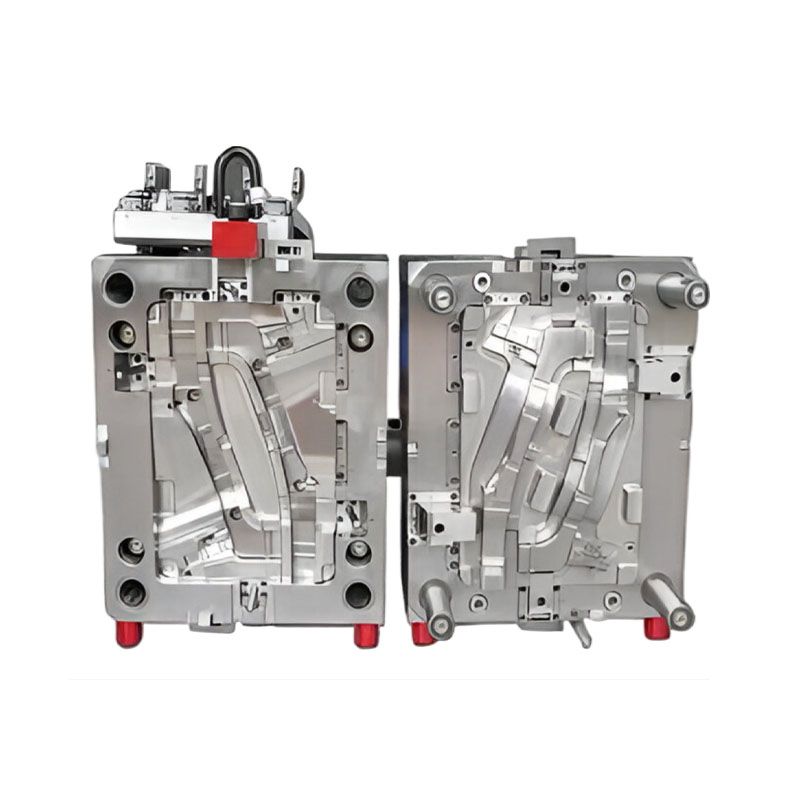

The company's business covers multiple fields such as automobiles, electronics, home appliances and medical care, including injection molds, which can meet the needs of different customers.

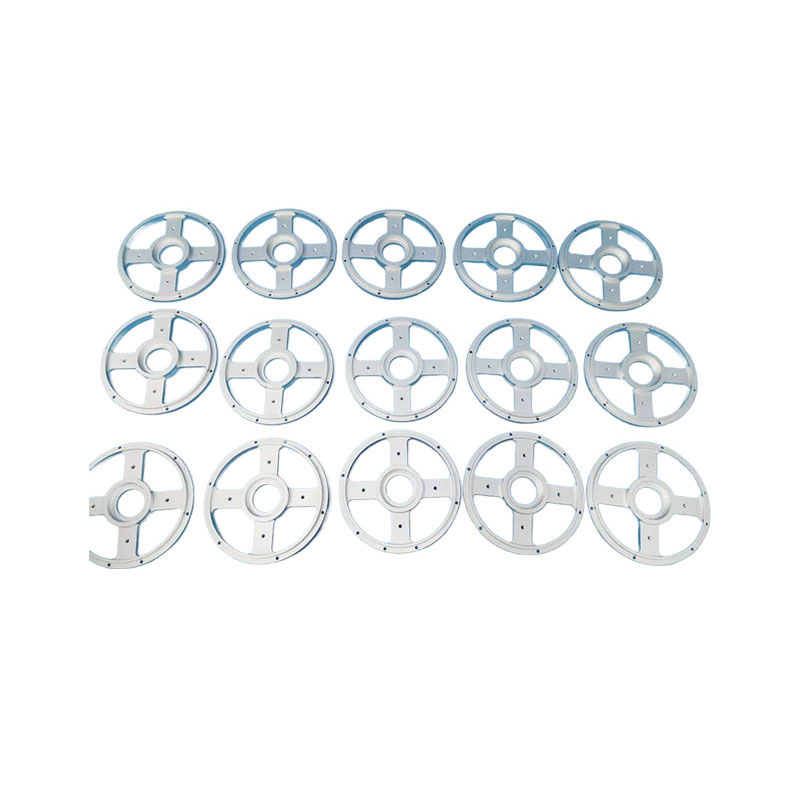

Provide injection molding services from small trial production to large-scale mass production, using high-quality plastic raw materials to ensure product stability and reliability.

Main production equipment

Our company has more than 10 large-scale mold manufacturing equipment, most of which are imported high-precision equipment. Including 10 high-precision CNC machining centers, mirror spark machines, slow-wire cutting machines, medium-wire cutting machines, EDM punching machines, grinders, milling machines, CNC deep hole drilling and other equipment. With efficient production processes and close collaboration, we can quickly respond to customer needs and ensure high-quality completion of the entire mold production as scheduled.

The injection molding workshop has more than 10 plastic injection molding machines (single-color and double-color), with machine tonnage ranging from 80T to 350T. All injection molding machines are equipped with robotic arm operations to reduce human resource losses, minimize product cycles, reduce costs for customers, and pursue maximum benefits. Managed by managers with rich experience in injection molding, we continuously improve quality, ensure a stable production process, and provide customers with high-quality products.

The prototype department has CNC, 3D printers, vacuum injection molding machines, and more than a dozen experienced prototype masters, who can provide customers with fast sample trials.

Adhering to the principle of "customer first, service first", we sincerely welcome people from home and abroad to cooperate with us to create a better future!

The company has domestic advanced mold processing and injection molding equipment, a strong design and development team, and can provide customers with a series of services from product design, prototype processing, mold production to injection molding. The company has passed the ISO 9001 quality management system certification, and strictly controls every link from raw material procurement to product delivery to ensure that the products meet international standards and customer requirements.

The company's business covers multiple fields such as automobiles, electronics, home appliances and medical care, including injection molds, which can meet the needs of different customers.

Provide injection molding services from small trial production to large-scale mass production, using high-quality plastic raw materials to ensure product stability and reliability.

Main production equipment

Our company has more than 10 large-scale mold manufacturing equipment, most of which are imported high-precision equipment. Including 10 high-precision CNC machining centers, mirror spark machines, slow-wire cutting machines, medium-wire cutting machines, EDM punching machines, grinders, milling machines, CNC deep hole drilling and other equipment. With efficient production processes and close collaboration, we can quickly respond to customer needs and ensure high-quality completion of the entire mold production as scheduled.

The injection molding workshop has more than 10 plastic injection molding machines (single-color and double-color), with machine tonnage ranging from 80T to 350T. All injection molding machines are equipped with robotic arm operations to reduce human resource losses, minimize product cycles, reduce costs for customers, and pursue maximum benefits. Managed by managers with rich experience in injection molding, we continuously improve quality, ensure a stable production process, and provide customers with high-quality products.

The prototype department has CNC, 3D printers, vacuum injection molding machines, and more than a dozen experienced prototype masters, who can provide customers with fast sample trials.

Adhering to the principle of "customer first, service first", we sincerely welcome people from home and abroad to cooperate with us to create a better future!